Both corrosion products are generated by the electrochemical reaction induced when a galvanic cell is formed between the copper core and the silver plating.

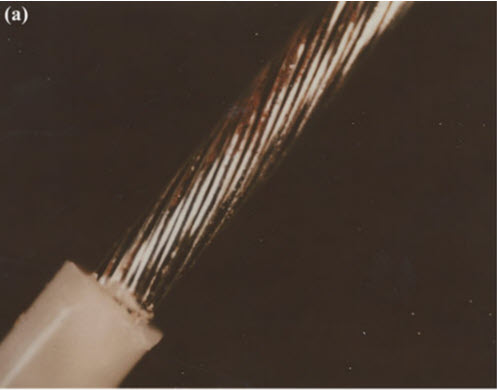

Silver plated copper wire red plague.

The environmental test system artificially promotes red plague corrosion under controlled laboratory conditions as a result of galvanic corrosion of the copper conductor core.

Most often it is seen as spots of brown or red on the silver plating.

Targeted for applications where exposure to assembly processes environmental conditions and contamination may promote the development of cuprous cupric oxide corrosion a k a.

There is an industry accepted method for measuring key factors in a wire s red plague susceptibility.

Silver however can tarnish and silver plated wire is susceptible to red plague if moisture gets between the wire and the insulation.

Red plague originates at breaks in the silver plating of copper wire strands in the presence of moisture and oxygen.

The term red plague was coined to describe the red cu 2 o and eventually the black cuo troublesome corrosion by products observed in silver plated copper conductors.

I ve never used silver plated wire for speaker cable personally so i have no opinion on sonic differences if there are any.

109 ft of silver plated copper wire only 105 ft i e.

The appearance of red coloured corrosion products on silver plated copper wire has led to the use of the term red plague to describe the problem.

Red plague is an accelerated corrosion of copper when plated with silver after storage or use in high humidity environment cuprous oxide forms on the surface of the parts the corrosion is identifiable by presence of patches of brown red powder deposit on the exposed copper.

Several investigative activities were undertaken by esa in the mid seventies.

The corrosion of silver plated copper wire has been a problem in recent years in the aerospace industry since this particular type of wire is used in electrical circuits where high reliability and long service life are basic requirements.

Some wire cable manufacturers have found a way to minimize the likelihood of red plague.

Red plague or cupros oxide is the name given to the corrosion effect found in silver plated copper wire.

Silver plated raw material must be kept in a low humidity environment below 50 percent relative humidity.

Red plague control plan rpcp scope.

Red plague of silver coated copper wire cable and harness assemblies.

Wire manufacturers must keep equipment in a clean environment.

These included laboratory evaluations a european red plague survey and eventually the.

Prescribes the minimum requirements for the control of cuprous cupric oxide corrosion a k a.

0 003 had a significant amount of red plague and that no malfunctions could be attributed to this phenomenon.

Most importantly wire manufacturers should avoid mechanical abrasion of the silver plated conductor in the stranding and braiding process.

Red plague forms when the silver plating is damaged exposing the copper wire to moisture or high temperatures.